Polyethylene Tubing

Specifications

- Flexibile

- Chemically Inert

- UV Resistant (Black tube)

- Temperature Range: -100°F to +175°F (-73°C to +80°C)

- Compare Other Materials

Polyethylene is the most commonly used tubing due to its flexibility, wide range of chemical resistance and lower cost. Nycoil uses high quality Linear Low Density Polyethylene material (LLDPE).

LLDPE has a much higher resistance to stress cracking as compared to other Polyethylene compounds. It is also chemically inert, meaning it forms a good barrier against moisture, vapors and gases – minimizing the possibility of leaks or contamination. Where prolonged exposure to sunlight or ultraviolet (UV) light is a concern, black tubing is recommended for extended life.

Typical Applications

- Potable Water Feed/Drains

- Pneumatic or Signal Lines

- Liquid/Air Transfer

| Polyethylene Fractional Tubing | |||||||||||

| Tube O.D. |

Tube I.D. |

Wall

Thickness |

Part Number | Min. Bend Radius |

Weight | Working Pressure |

Burst Pressure | Color Code | |||

| 100' | 500' | 1000' | |||||||||

| inch | inch | inch | Reel | Reel | Reel | inch | 1000" (lbs.) | psi@68°F | psi@125°F | psi@68°F | Suffix Key |

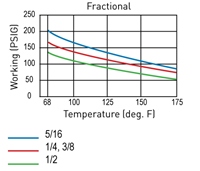

| 1/4 | .170 | .040 | 6244_ | 6444_ | 6644_ | 3/4 | 1.9 | 160 | 95 | 500 | 0 = Natural 1 = Black 2 = Red 3 = Blue 4 = Green 5 = Yellow 6 = Orange 7 = Gray |

| 5/16 | .190 | .062 | 6255_ | 6455_ | 6655_ | 5/8 | 2.2 | 193 | 121 | 600 | |

| 3/8 | .250 | .062 | 6266_ | 6466_ | 6666_ | 1-1/8 | 25.3 | 167 | 107 | 500 | |

| 1/2 | .375 | .062 | 6288_ | 6988_* | 6688_ | 2-1/8 | 35.5 | 120 | 78 | 400 | |

* Indicates 250' Reel

Adding a Color Code suffix to the part number is required. If no Color code is selected, Natural (0) color will be supplied. Custom sizes, cut lengths, reel lengths and colors are available upon request - contact Customer

Service

Adding a Color Code suffix to the part number is required. If no Color code is selected, Natural (0) color will be supplied. Custom sizes, cut lengths, reel lengths and colors are available upon request - contact Customer

Service

| Polyethylene Metric Tubing | |||||||||||

| Tube O.D. |

Tube I.D. |

Wall

Thickness |

Part Number | Min. Bend Radius |

Weight | Working Pressure |

Burst Pressure | Color Code | |||

| 100' | 500' | 1000' | |||||||||

| mm | mm | mm | Reel | Reel | Reel | mm | 1000" (lbs.) | psi@68°F | psi@125°F | psi@68°F | Suffix Key |

| 4 | 2.5 | .75 | 7203_ | 7503_ | 7803_ | 12 | 5.0 | 200 | 125 | 600 | 0 = Natural 1 = Black 2 = Red 3 = Blue 4 = Green |

| 6 | 4 | 1 | 7206_ | 7506_ | 7806_ | 36 | 10.2 | 167 | 110 | 500 | |

| 8 | 6 | 1 | 7208_ | 7508_ | 7808_ | 48 | 14.2 | 117 | 70 | 350 | |

| 10 | 8 | 1 | 7211_ | 7511_ | 7811_ | 60 | 18.3 | 83 | 50 | 250 | |

| 12 | 9 | 1.50 | 7213_ | 7513_ | 7813_ | 70 | 31.5 | 117 | 70 | 350 | |

Tube Cutter

| Part Number | |

| Tube Cutter | 60001 |

- Corrosion resistant hardened steel blade assures straight, crisp cuts for optimum fitting connection

- Replacement blades can be installed in seconds using only a screwdriver